Project background

After the first workshop in 2013, last summer ILWP and the local association Berimbau de Ouro organised a new workshop in Montes Claros, Brazil. The project, funded by Ramboll foundation, was led by two bright structural Engineers of Ramboll UK – Mark Bridger and Nick Smallman – together with Marco Ogno from I-Love-WindPower, who spent more than a year to prepare and then execute it.

Key people in the execution of the project. From left to right – Luis Carlos Afonso (Berimbau de Ouro), Nick Smallman and Mark Bridger (Ramboll UK), Peter Cezar, Oliver Oliva and Marco Ogno (ILWP)

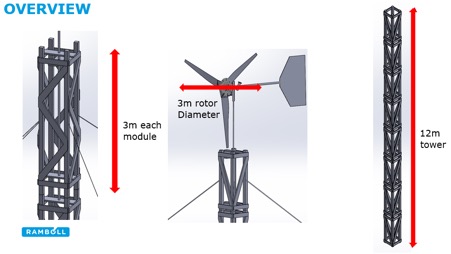

One of the biggest challenges for locally sourced hand-made wind turbines in developing countries, is the difficulty in sourcing the metal (due to cost, quality and availability) necessary to build the traditional 12-15 meter tall metal tower to install and operate the wind turbines. Therefore the main scope of the project is really ambitious: design a low cost modular wooden tower and then teach the Brazilians how to build and install such a structure. In addition to this, the project aims to give a workshop on how to build a hand-made wind turbine and how to assemble and connect the whole electrical system to power electrical appliances.

Before leaving for Brazil

In order to succeed, the team has first to test their wooden tower design (see other post in July 2015 at: ramboll-wooden-wind-turbine-tower-design), and then learn how to build an aero-generator before leaving for Brazil. This latter milestone is achieved in May 2015 with the help of the association V3 Power, that with their amazing 3-day course in London, enables the team to absorb the know-how and knowledge before leaving for Brazil

V3 power Workshop in London – Adam Lord, Marco Ogno, Mark Bridger and Nick Smallman receiving the certificate of participation for the course.

Last thing to do before leaving is to collect the anemometer that the team will be installing in Brazil to capture and monitor wind speed over time at different locations. Once again V3 Power, with the help of Jack and Tom, help us to get the components in time!

…It is now July 2015 and the team is ready to leave for Brazil, where the real adventure starts…

In Brazil – the story by Marco Ogno

On the 12th of July we all three meet at International Airport of Rio de Janeiro and we settle in a hostel in the heart of Rio. The plan is to spend 2 days in town in order to collect an old and damaged 3m diameter wind turbine, its electronics, some tools and the x4 12V batteries that have been left by ILWP in 2011 during the Rio+20 conference.

Job that sounds quite easy, but probably the most challenging of the whole trip. First, the turbine and all the material need to be collected from the other side of Rio from where we are, approximately 8 km. Secondly the blades are broken, still on the turbine and difficult to remove, and the electronics is fixed to a 2mx1.5m wooden panel that is impossible to transport. Finally the batteries are huge, weighing approximately 20 kg each, and not many Brazilians want to load them in their car. We decide to saw the blades, cut the electronics board in pieces and manage to convince a taxi driver to transport everything to the hostel where we are staying! What an effort!! But we succeeded!

After a deserved celebration for the success, we spend the next day trying to book our 14hr bus drive to Montes Claros and to pack all the material collected in a way that can be easily transported. Also this task reveals to be quite challenging as we discover that batteries are not normally allowed on buses, and they need to be “packed” in a specific way. The day after we are ready to try the boarding… and after having negotiated the local handling fees, we are on it!

Workshop preparation

At Montes Claros Luis and Marianne, from Berimbau de Ouro, are waiting for us. As soon as we arrive they help us to load everything on to the truck and leave for our new home for the length of the workshop. We are two days late on our plan, and we need to squeeze into 3-days the whole preparation of the workshop.

Luiz Carlos Afonso, Marco Ogno, Mark Bridger and Nick Smallman collecting material and tools from the Fazenda Mandacaru’, (2013 workshop location, 35Km outside Montes Claros centre).

The next days are intense: we collect and check the integrity of the tools and materials left over from the previous visit in 2013, we buy the missing material necessary to start the new workshop and we inspect the location where we will be teaching, building and installing the new turbine: the capoeira school of Berimbau the Ouro, just outside the centre of Montes Claros.

Unfortunately the location is quite different from what we expected, and although perfect location for giving the workshop, we quickly realise that is not suitable for assembling and installing the designed 12m wooden tower. The location has a poor ground for the foundations and it is surrounded by many buildings and trees that could shield the turbine from catching the wind. Therefore the team, together with the consultation of the locals, decides to change the original plan and aims to position the turbine on top of a pre-existing water tower. The electricity generated will then be used to power the pump that fills up the water tank, proving and showcasing the working principle of the wind generator. For this, a smaller wooden tower will be designed, produced and installed.

It is Friday evening, we are exhausted but we are ready to start the workshop the next day– A good night of sleep and we are ready to go!

The workshop

We arrive at the school early in the morning and we are delighted to see, meet and greet a great number of people, all with a good mix of age, background and provenience: University students, craftsmen, capoeira students and local people that live in the area and heard about the project.

Closing break after the first day of workshop at the capoeira school of Berimbau de Ouro, Montes Claros, Brazil.

In the next days the workshop runs at its best, with three fix stations where Mark, Nick and I respectively teach wood, metal and electronics to the people attending. Mainly due to their different employments, day after day we see that new people will join, others will leave, and other will leave for coming back after work. Anyway every day we have 8-10 attendees, which gives just about right number of people at each station.

Figure 7: Electronic station. Marco Ogno teaches the group how to connect the coils in the stator. Clockwise from the teacher (cream T-shirt), Admo Macedo, Carneiro Soares Andrade, Igor Lucas, Herbert Pereira, Peter Cezar, Line Lauridsen, Oliver de Oliveira Oliva Filho and Tjackmda Silva

Electronic station. Marco Ogno teaches the group how to connect the coils in the stator. Clockwise from the teacher (cream T-shirt), Admo Macedo, Carneiro Soares Andrade, Igor Lucas, Herbert Pereira, Peter Cezar, Line Lauridsen, Oliver de Oliveira Oliva Filho and Tjackmda Silva

In each free moment from teaching, with the help of Luis, one of us goes shopping to buy the material needed for the next phases of the workshop. These are busy days, running workshop for 8 hours, and using the remaining time to clean, buy missing materials and prepare for the next day of workshop.

However hard work pays off, and in a week we managed to finish building the generator, the blades and we are ready to assemble the 3m rotor diameter wind turbine.

These are amazing days, where we not only teach people about turbines, but mostly we learn from each other about different habits, music, food and costumes….we are exploring each other’s cultures! Despite our poor Portuguese and their basic English, we manage to communicate really well, as we quickly realise that words are just one of the many ways you can exchange information and feelings with these amazing people.

Luis, being also the master of the school, invites us regularly to join the capoeira classes that he and his teachers give at the school in the evenings… This is where, at rhythm of the music, we play and again learn from each other, independently from who we are and where we come from.

Marco, Mark and Nick and some local students receiving a capoeira lesson from Luis, Master “Marreta”, the owner of the school.

As we get closer to the locals, they get closer to us. The people from Montes Claros are getting excited about the workshop, therefore we decide to showcase one of the old wind turbines on a tripod. In this way everyone coming into the school can see and play with the turbine.

Soon the local television comes to interview us, the Capoeira School and the students. You can watch the full video here.

The reportage that was given on the local television by the No.1 National TV provider “Globo”, where Marco Ogno explains with “his” Portuguese the reason for the workshop, how the turbine works and what can be done with it.

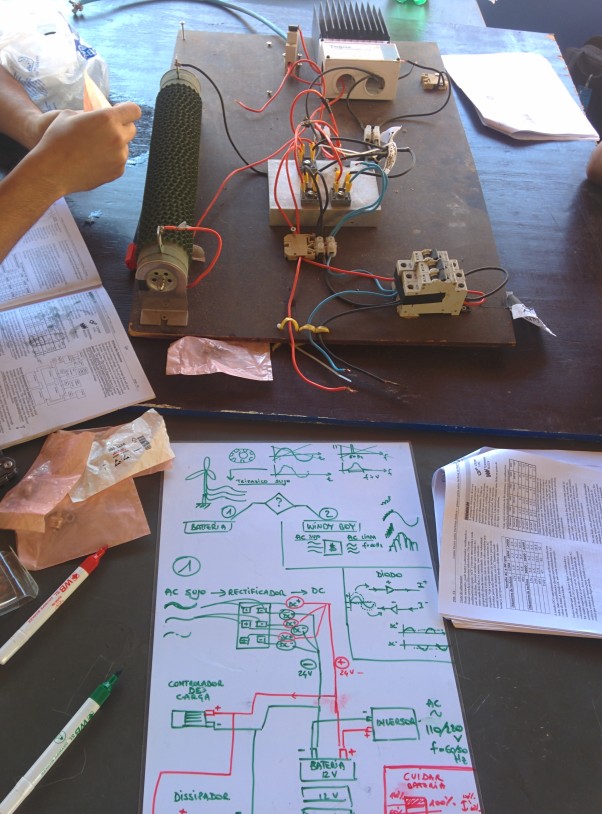

We are now entering in the second week of the workshop, and we are busy with building the wooden tower and its connections, building the electronic panels for the conversion of the electricity and finally planning the installation of the turbine on top of the water tower.

These final tasks are an extreme challenge, not only because the tower structure and foundations needed to be re-designed to fit on the water tower, but also for making sure that the installation’s site will be safe to access and work on. Therefore we keep the group separate, and while part of the team will work at building the tower and the foundations, the other will be working to the electronics panel.

The next three days are really long ones, made of continuous trials and errors during the daylight and thinking and solution design during the evening. However with great individual effort and incredible teamwork, we manage to finish to build the wooden tower, the electronic panel and to find a way to lift all the equipment on top of the water tower for the final installation.

…It is 9pm of the 28 July 2015 and Luiz, Mark, Nick and I are sitting at the usual Point do Acai (Acai bar) on the main boulevard of Montes Claros. It may seem one night like any of the others that we have spent in town; in fact we are all tired, dirty, hungry but happy. However tonight is different… We completed the workshop and managed to install the wind turbine at the Berimbau de Ouro School in Town! Yehaaaaaaaaaaaaa!

Mark, Nick and Herbert Luiz celebrating the installation of wind turbine on top of the water tower, at the Capoeira School.

Wooden tower design workshop

We have five more days to stay in town and, although they may not be enough, we have all agreed to try building the original 12m modular wooden tower, designed for the Brazilian project. The schedule is tight but we think is the right thing to do, as we have few more days, a suitable location – Luis’s farm, the “Fazenda Mandacaru’” – an old turbine to install, few students happy to continue to support us and enough money left in the bank account.

On the same day we buy all the necessary material and then drive to out of town to the Fazenda Mandacaru’ to prepare the workshop for the next day.

The first day of the tower workshop we manage to teach them the standard building sequence and, working in parallel, by the end of the day we have complete most of the module’s faces.

Nick Smallman (and Mark Bridger – not in the photo) teaching the building method and sequence of the first wooden tower module’s face.

Although time consuming, the step by step instructions developed during the design phase are simple and easy to follow. In fact, in the workshop everyone manages to assemble the individual modules without problems.

In the next days the focus will move from building the modules, to assemble the whole structure. We quickly start to realise that connections between modules, lower inches for the foundation and upper connections to hold the wind turbine on the top of the towers are more challenging than we expected.

Nick and Mark work full time to adapt their original wooden tower design to local materials and environmental conditions, while Me and the other people start to prepare the area chosen for the installation. We dig the holes for the four anchor points, we connect the anchors and the guy wires to sustain the tower, and we prepare the cement to cast the foundation and the inch system for the lifting of the wooden tower.

Due the huge amount of work, the days literally fly away, and by the time we finish the final assembly we appreciate that there is no time for installing the turbine together with the its electrical system. We agree to use those last hours of work at the fazenda to prepare the tower and the turbine for the lifting operation and write down a step-by-step guide on how to erect and connect the turbine to the electrical system.

Final assembly of the 12m wooden tower, ready for installation at the Fazenda Mandacaru’ – Montes Claros, Brazil.

Tonight is the last night that we will be spending in Montes Claros and, although we will not be able to install the second turbine, we want to celebrate with all the local people this amazing cultural experience and our incredible achievements!

Therefore the project closes as it started: with food, drinks, music, capoeira dances and smiley people, all together in a colourful night in the middle of the Brazilian winter.

Celebration party open to all the people involved in the project and living in the quartier around the Capoeira School in Montes Claros.

If you are interested in this project and its development, please like and follow our facebook page

If you would like to volunteer and help us to develop in Brazil or in other development countries, please do not hesitate to contact us – we are always looking for support.

Greetings

How did we manage to do all of this? I am not quite sure…the only thing I am sure of is that we would have never been able to do it without the help and the dedication of all the people involved in this Project! In many stories the Author tends to write “thank to all”, but since this is my story I will try to write the names of all the people who make this possible:

Luiz, Marianne, their family and Berimbau de Ouro for the whole organization and support.

Mark, Nick and Ramboll UK and Ramboll Fundation for funding the project and sharing their engineering knowledge.

Piet, his wife Isabel and all the other volunteers from ILWP who continuously support the project.

Jack and Tom, together with all V3 Power guys, who helped us with the hardware and software supply and trainings.

Alex da Silva and Hugh Piggott who allowed us to have the Portuguese manual on time to deliver the workshop.

All the Brazilian people who attended the workshop and who are bringing the project to the next level, as: Oliver, Peter, Herbert, Farley, Admo, Jack, Tiago, of the local Brazilians attending the workshop!

OBRIGADO,

Marco